Solid-State Technology

Our sensors offer extreme durability for extended product lifespan.

Detect through Non-ferrous Materials

Capable of measuring through up to 20mm of non-ferrous material.

Integrated and Semi-Remote Electronics

Integrated CPU’s deliver ratiometric analog or CAN outputs.

Full Customisation Capability

Our sensors are designed to fit your specific application.

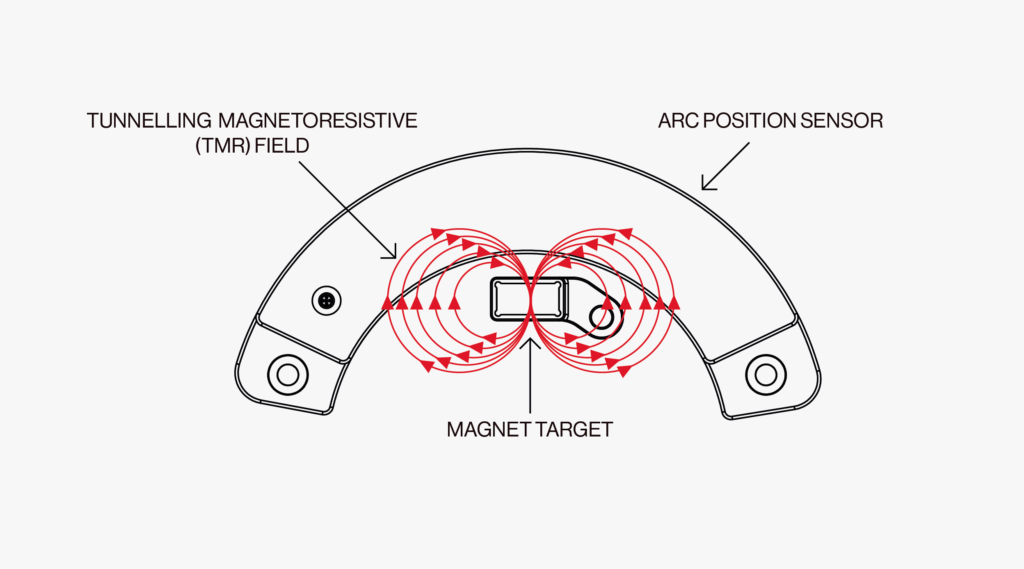

How do Tunnelling MagnetoResistive Position Sensors work?

Our Tunnelling MagnetoResistive position sensors are constructed of a number of sensing heads and process electronics within a single housing, and a target magnet that is usually fixed to the component being measured. As the component and target magnet moves, the sensing heads measure the change in magnetic flux angle of the magnet target. This technique allows our TMR position sensors to measure through up to 20mm of non-ferrous materials such as stainless steel, aluminium and carbon fibre.

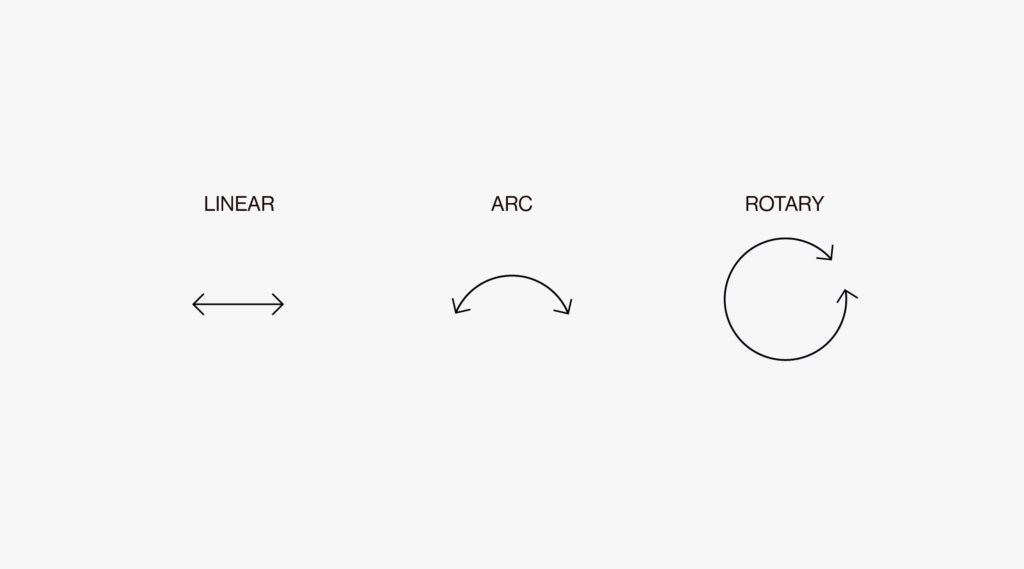

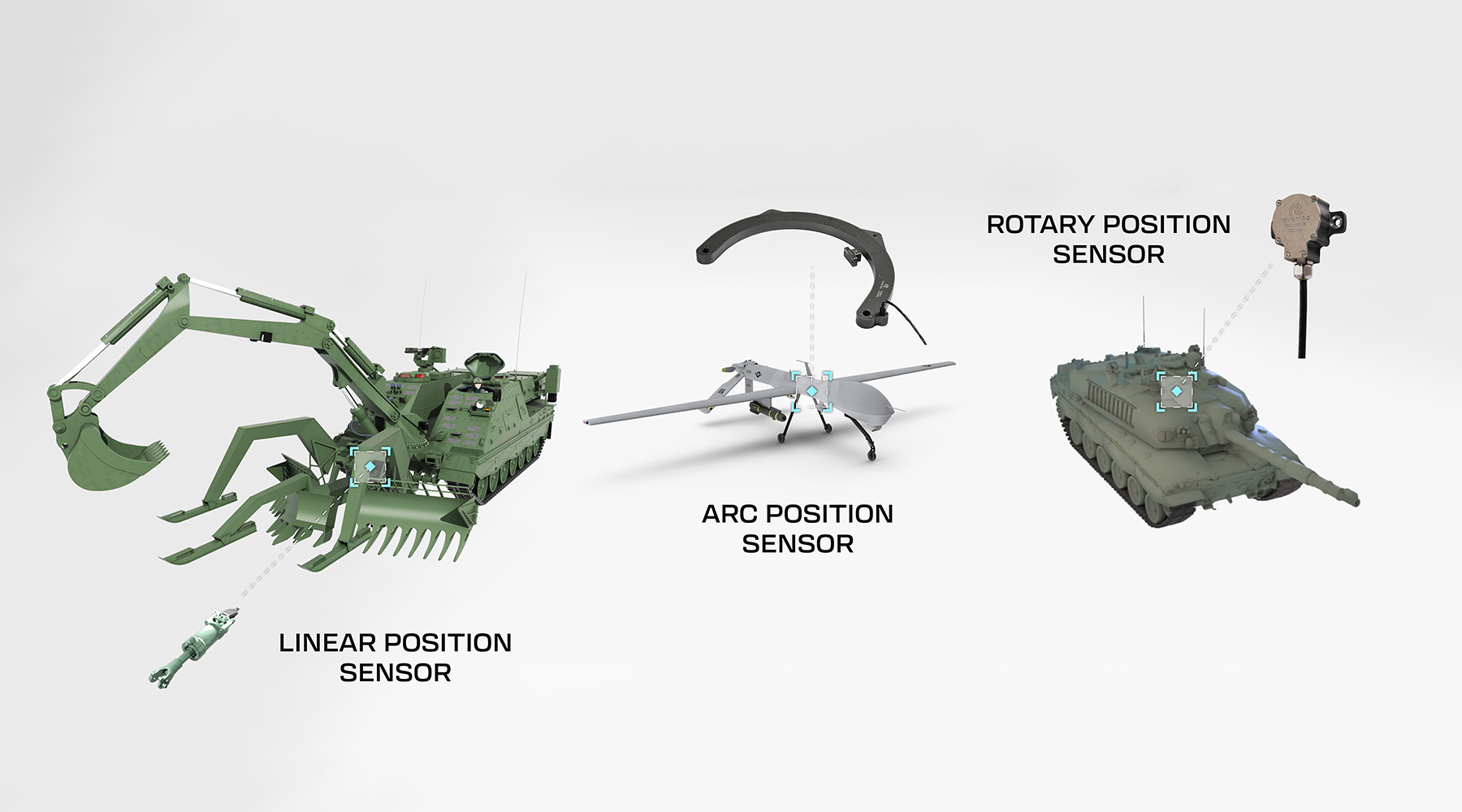

3 Measurement Paths

We have three movement paths that we can measure: linear, arc and rotary.

All of our position sensors are factory calibrated to the specific measurement length and path type to achieve advanced accuracies of ±0.5% of reading, ensuring simple plug and play installation.

Extremely Versatile

All of our sensors are engineered to endure extreme environments such as high vibration, high and low temperatures, and dust ingress. Our tailored TMR position sensors are designed to fit your spatial constraints and are manufactured in any shape, any size and many materials. All Quantum TMR position sensors can be modified to your specifications through specific housing geometry and material, cable length and/or choice of specialist connector.

What are the benefits of Tunnelling MagnetoResistive Position Sensing compared to other technologies?

Our Quantum TMR™ technology is forged from quantum physics and tunnelling magnetoresistance for superior measurement performance compared to other common magnetic techniques, such as Hall effect sensors. We manufacture and calibrate our Quantum TMR position sensors to your custom measurement range and build bespoke sensor housings designed to fit your spatial requirements.

- Superior Field Sensitivity for Higher Precision

Typically our TMR position sensors sensitivity is over 1000 times that of a standard Hall effect sensor. - Detect through Non-Ferrous Materials

Position sensing through up to 20mm of non-ferrous material, such as aluminium or stainless steel, and across up to 40mm air gaps from sensor to target, subject to target. - Advanced Accuracies

TMR position sensors deliver a high accuracy, low noise signal even when the target magnet is up to 40mm from the sensor. - Designed for Durability

As a non-contact, solid-state technology we eliminate the risk of mechanical wear.

OUR PRODUCTS

Explore our range of TMR position sensors.

Specifications

| Measurement Paths | Linear, Arc and Rotary |

| Outputs | Analog, CAN, Analog & CAN |

| Accuracy | ±0.5% |

| Operating Temperature | -40°C to +150°C |

| Response Rate | Up to 5kHz |

| Mounting Options | Multiple available |

Mil-Std EMC Certified

Vibration Tolerant

Ingress Protection up to IP69K

Insensitive to Orientation

Made in

the UK

CE & UKCA Compliant