Position Sensors

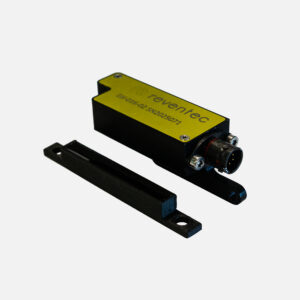

Reventec position sensors use magneto resistive TMR technology to measure linear, angular and rotary movements.

Capable of measuring through 40mm of non-ferrous material, the sensors are non-contacting solid-state devices, ensuring accuracy and reliability unmatched by potentiometers and other legacy technologies.

Reventec is a specialist engineering design consultancy based near Salisbury, UK.

Our design team develops position sensors that use magneto resistive TMR technology to measure linear, angular and rotary movements. We produce a range of standard and customisable position sensor configurations, as well as offering fully-customised designs.

Our programmable non-contact position sensors offer high accuracy and long-term reliability in harsh environments. For that reason, our customers often operate at the cutting edge of motorsports, defence manufacturing, industrial automation and the automotive industry. They value our technical expertise but also our fast response times. We specialise in taking products from concept to production in quick time.

Reventec is set up specifically to provide design consultancy, prototyping and one-off or small-batch production runs. We can scale up production to 5000+ pieces, as required.

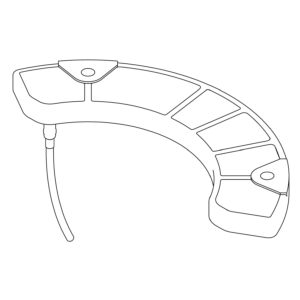

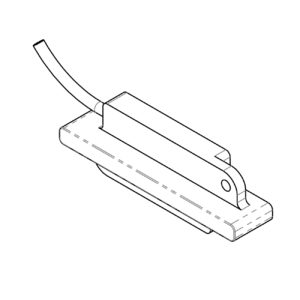

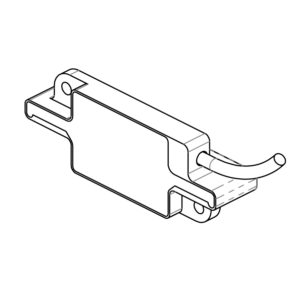

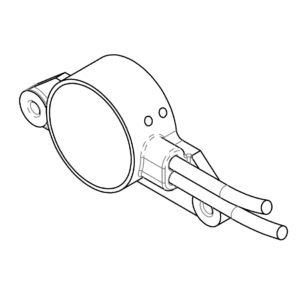

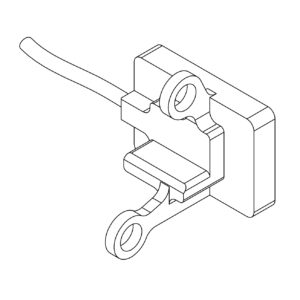

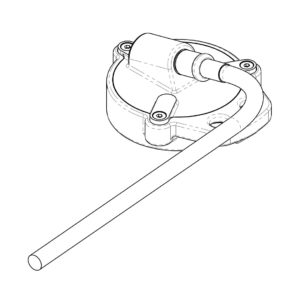

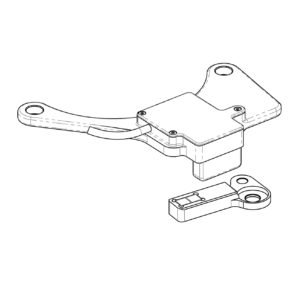

Standard position sensors for rotary and linear position measurement, available for immediate delivery.

Custom Position Sensors

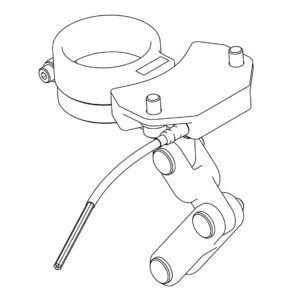

We design and develop fully-customised position sensors for harsh environment applications. Whether you have a 1-off prototype requirement or require full volume production, we have the skills and experience to deliver a suitable solution. Our position sensor customers include Formula 1 race teams, America’s Cup sailing teams, military and industrial organisations, amongst a wide variety of others.

The products below represent a small sample of the custom sensors we’ve designed and manufactured to specific customer requirements.