Description

The brief

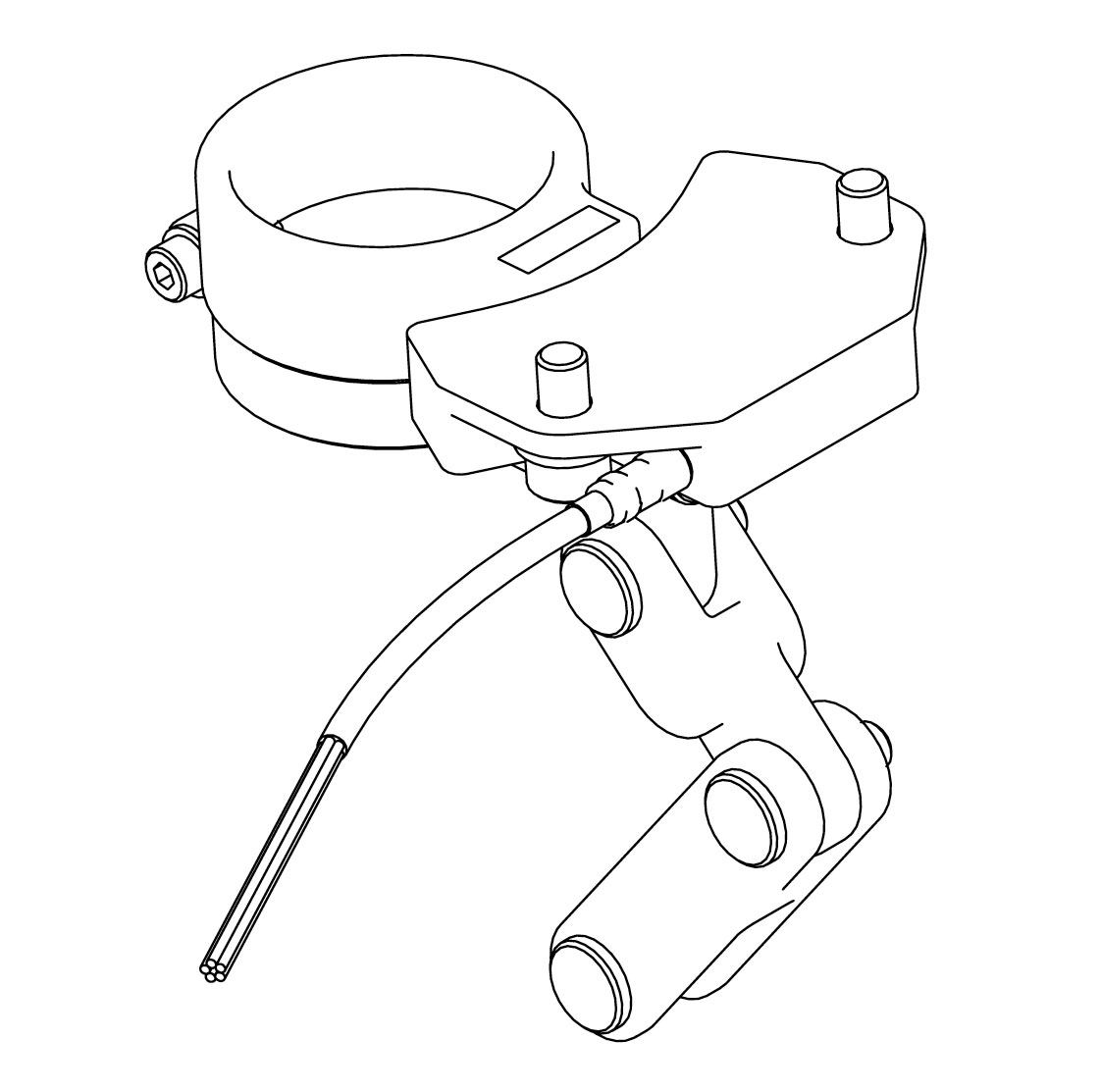

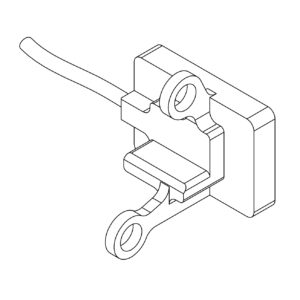

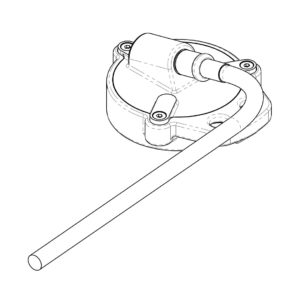

An America’s Cup yacht racing race team approached us to design a mast rotation position sensor. The sensor had to monitor up to 90 degrees of arc movement. It also needed to provide accurate monitoring.

This was a particularly complex project. The sensor had to monitor an arc movement, while also subject to pitch and roll on a ball joint. We also had to factor in a varying measurement gap. In addition, the sensor needed to withstand a harsh marine environment. This was a challenging but interesting project.

Reventec develops sensors for top-flight motorsports and we understand the challenges of racing under harsh conditions. As a result, we were briefed to design and produce a reliable sensor.

Reventec position sensors use the latest TMR non-contact sensing technology, so they don’t suffer from the same physical wear characteristics of potentiometers or other legacy technologies.

Our customer received a 3D printed prototype assembly in just two weeks.

About Reventec

We measure linear, angular and rotary component movement using the latest TMR technology. Legacy technologies can’t deliver this level of accuracy or reliability. Our sensors are non-contact and can measure through 40mm of non-ferrous material. They are ideal for use in harsh environments because they are solid-state.

Our sensors are factory calibrated to a user’s specifications and they can be programmed by users using a simple GUI, supplied free of charge.

Reventec also designs and builds capacitive liquid level sensors and programmable temperature sensing solutions.

We produce a range of standard and customisable sensor configurations. We also offer a full custom design service.

Reventec customers value our technical expertise and fast response times. They typically operate at the cutting edge of:

- Motorsports

- Defence manufacturing

- Industrial automation

- Automotive industry

Reventec provides design consultancy and one-off / small-batch production runs. We also offer production runs of 5000+ pieces, as required.