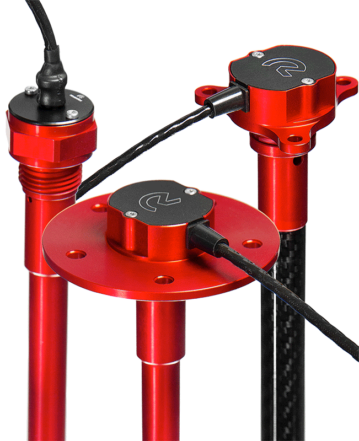

Liquid Level Sensors

Solid-state capacitive liquid level sensors for continuous measurement of fuel, oil, water and coolant. Built for high precision in harsh environments.

Sensors for Extreme Environments

Solid-state capacitive liquid level sensors for continuous measurement of fuel, oil, water and coolant. Built for high precision in harsh environments.

| Accuracy | ±0.5% |

| Operating Temperature | -55°C to +150°C |

| Supply Voltage | +6 – +30 VDC |

| Mounting Options | Multiple available |

| Configurable Length | 60 – 700mm |

| Outputs | Analog, CAN, Analog & CAN |

Mil-Std EMC Certified

Vibration Tolerant

Ingress Protection up to IP69K

Insensitive to Orientation

Made in

the UK

CE & UKCA Compliant

Customisable.

Choose from full custom development,

semi-custom or a sensor from our core range.

Discover what capacitive liquid level sensing is and how we harness this technology across our range of fuel, oil, water and coolant liquid level sensors.

Our mission is to engineer sensor solutions that solve our customers measurement challenges. We have experience in a variety of applications over the last few decades and are well-equipped to offer innovative highly-customised, bespoke sensors and off-the-shelf products. Explore how we develop our sensors for each application and view our current product ranges.

Engineered for accurate measurement to keep your equipment performing.

Our standard options are; 1-bolt, 2-bolt, 3-bolt, 5-bolt SAE, AN-8 threaded (9/16UNF) and AN-10 (3/4UNF). However, if these do not fit your requirements, please contact one of our engineers to discuss our wide range of custom flange arrangements.

As standard, the sensors have been designed for IP67, however we have customised solutions for up to IP69X.

Yes. All of our sensors are made to order in-house so we manufacture the cable length to the customers specification.

Nominal weight for a 300mm sensor is <100g, including cable.

Typical lead times for our standard products are 2 – 3 weeks, however we can offer expedited manufacture if required. Please talk to a Reventec sales representative for more information.

Reventec sensors are compatible with all common automotive, heavy machinery and industrial fluids.

Read our latest case studies to discover how we provide sensor solutions for our customers to meet their business objectives.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |